During the year of 1950, Henri was asked to make a model of a Alfa Romeo Type 158, the full-sized car belonged to a millionaire shipping magnate. The brief was that it had to be a working model, with a fully working supercharged eight-cylinder engine, all to scale in every detail. It was a truly daunting project, but because it was such a challenge, Henri took it on. It is difficult to explain how fussy this customer was and how determined to keep to a very tight budget. A previous model we made was returned because I had managed to accidentally put my thumb-print on it while packing it. It was meant to show how terrifying his financial power was, I guess. This project ran concurrently with others, which often happened because there was always a cash-flow problem. I will attempt to give some idea of what he was like. He invited me to tea one afternoon when I was first in the Royal Air Force, doing my first few weeks training. He was living in a massive mansion about twenty miles from the camp so I took the bus and walked down his very long drive to his mansion and rang the bell. A most beautiful French lady opened the door and invited me in to the drawing room where Mr S…. was waiting. He left me to have tea with his lovely young wife and disappeared. Later he showed me his collection of classic cars. Among them was a Rolls, a Bentley, a superb Alfa Romeo P4 voiturette racing car, a Hispano Suiza of gigantic size and a massive and sleek Bugatti. He took a clean white handkerchief out of his pocket and instructed his chauffeur/mechanic to wipe it under the chassis of any of the cars of my choice. I chose a car that he had used the day before, the Rolls, and the handkerchief came away spotlessly clean. The chauffeur told me later that his master would sack him on the spot if the cars including the chassis were not spotlessly cleaned after every outing. Mr S…. showed me his collection of models that he had gathered in his travels. He had travelled considerably. There were sailing ships made entirely of bones by French prisoners in South America, which he had bought for a miserable sum. They must have taken years to make. He also had model steam-trains made by the very best railway modeller in the world at that time, George Beeson. Henri knew George and respected him greatly for his wonderful works of utmost perfection. They really were facsimiles of the real thing. Mr S…. did not appreciate the work that had gone into them, so we could not expect him to value our work properly. After Henri made him a couple of models, Mr S…. added an Alfa Romeo 156 to his collection of full-sized cars and the project was mooted, drawn up, and the work begun.

Henri really went to town and made a box-wood pattern and cast the cylinder block and crankcase using a little Tortoise stove in the workshop. The stove would be red-hot when pouring was imminent to get the aluminium to melt properly before impurities were skimmed off the surface. This was a very dangerous operation as the workshop had a pine floor and the rest of the structure was entirely made of cedar. It was exceedingly difficult to pour the casting without getting any air-holes in the block. He moulded two to be on the safe side so that when it came to machining he would not have to start all over again with casting. One mistake at the machining stage would have been disastrous as several days work would have been wasted and no money earned. Henri made adapters for his Myford lathe to enable him to mill similar projects some years before. The long cross-slide was designed and made by himself, which Myfords have produced for many years as an accessory to the 7 series. For more on this click here. This enabled reverse turning which enabled much deeper cuts when roughing out. It also produced a better finish, as the arbour was more stable.

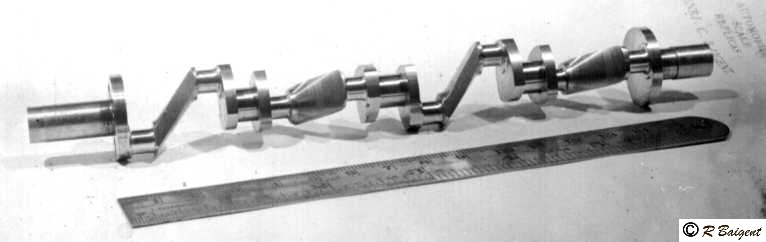

the crankshaft after being turned in one piece

The Alfa crankshaft was turned from one piece of S11 stainless steel, left over from World war II workshop projects. The spark-plugs were made specially to scale for him by Champion as a gesture of good-will, which was most helpful. To find a sponsor at this stage was so helpful financially. The valves and guides were turned and ground, and he had started to make the valve springs. The working supercharger case was made and fitted.

The con-rods were half made when there was a disagreement about progress, pricing, and the terms of the contract, so work was suspended until that could be resolved. Sadly, it never was finished, as it was never resolved, and so I have kept the remains as safely as I can, but it is very doubtful that it will ever be finished now. I have this engine in my collection, stored in a very secure place. As I have just had my eyesight restored recently, I hope that I will be able to find the time to progress the project before the 'Grim Reaper' catches up with me!

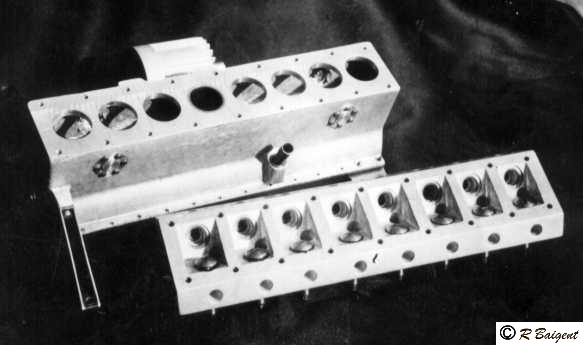

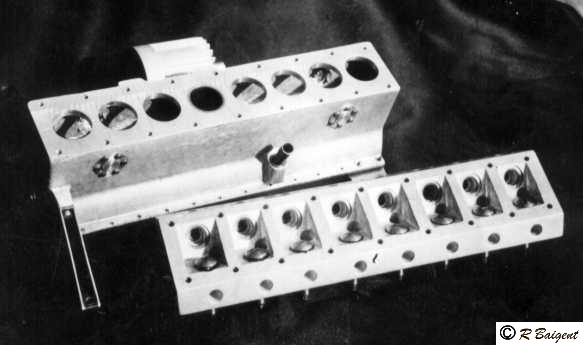

some parts of the Alfa 158 engine before assembly, click on picture for larger image

the main block assembled before crankshaft was fitted, click on picture for larger image

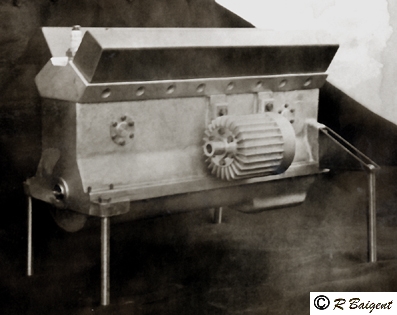

complete assembly with rocker-covers fitted

I have enclosed a drawing of an Alfa type 158 for any aspiring modeller, click on image to enlarge